Multi-functional CNC lathe / Mechatronic lathes

The PROFITURN MULTI is a new series of CNC teach-in lathes specially designed for the European market

- The machine bed is with natural gap and the accessories and options allow for a wide range of uses in any workshop

- Precision ballscrew, high rigidity precision compound bearings ensure accurate positioning and efficient driving. Centralized oil lubricator providing forced automatic lubrication onto ballscrew and mating surfaces

| Paraméter | Egység |

| Gépágy fölötti átmérő | mm |

| X tengely lökete | mm |

| Z tengely lökete | mm |

| Maximális esztergálható hossz | mm |

| ágy szélessége | mm |

| Keresztszán feletti átmérő | mm |

| Tokmány átmérő | mm |

| Főorsóvég | |

| Főorsó fordulata | ford/perc |

| Főmotor | kW |

| Szegnyereg dugattyú átmérője | mm |

| Szegnyereg dugattyú max. lökete | mm |

| Vezérlés | |

| Géptömeg | kg |

MULTI CNC PT-040-500 500 280 930 1430 1930 1000 1500 2000 400 280 ⌀250 A2-6/D6 7-135 30-550 11 7.5/11 75 150 SIEMENS 802C 2600 2700 2800

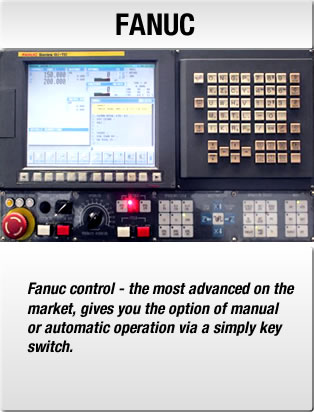

The Fanuc 0i control gives you the option of manual or automatic operation and includes over 200 standard features including Custom Macro B, Rigid Tapping and 256K Part Program Memory. This control will immediately increase your productivity and will continue to do so year after year. In manual mode it employs Fanuc’s latest version of Manual Programming Turn which is acclaimed to be the simplest and most user friendly teach lathe control in the world. In automatic mode we use Fanuc’s powerful CNC interface for the simple generation and execution of ISO programs. The combination of these two systems on one machine means that the Mechatronic Multi CNC is the most capable lathe available in its class.

The Siemens CNC control is a single unit, operator panel-based control system that includes a numerical control (NC), programmable logic controller (PLC), and human machine interface (HMI). It is capable of five-axis machining (two of which may be spindles) and is ideal for the low- and medium-range milling and turning machine markets. The product’s benefits include increased efficiency and productivity; convenient operation and programming through advanced programming support, such as Siemens’ ShopMill and ShopTurn; and perfect handling via commercially available compact flash (CF) boards for storage, transmission, and processing of part programs. Standard Ethernet and PROFIBUS protocols are used for machine tool communication.

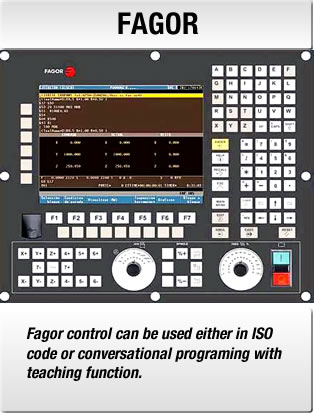

The Fagor control is a powerful CNC designed to meet the most demanding Machine-Tool applications: lathes and turning centers, milling machines, machining centers and general purpose applications. Thanks to is great calculating power and processing speed, they offer high-end features with the maximum programming versatility. Easy to program thanks to its profile editor and its interactive editor. Easy to install thanks to its PLC Logic Analyzer.

One of the advantages of the Mechatronic Multi CNC System is that you are always in control of the machine and you can manually override machining at any time to gain confidence or to hit the optimum tool performance.

Manual Turning

Turn the key and you are turning manually. It’s as simple as that! The manual screen display shows X and Z positions just like a DRO plus spindle speed, tool number and feed rate. Even if you haven’t used a lathe since your schooldays you could walk up to an Mechatronic Multi lathe now and cut metal.

Semi-Automatic Turning

With the Mechatronic Multi CNC System, a wealth of semi-automatic turning operations can be performed. These include parallel turning to stop positions, chamfers and radii, tapers, threads grooves, box cycles and even contour shapes. These can be linked together to produce even the most complex of components quickly and efficiently. What’s more, the easy to understand shop floor language coupled with touch screen simplicity means that an operator can learn to machine parts quickly.

Mechatronic Multi CNC offer the widest variety of control levels from manual through to full ISO on the one machine. Tailored to optimize the skills of the machine operator the Mechatronic Multi CNC Series offers a large machine envelope for the efficient production of a wide variety of components in small to medium size batches.

Mechatronic Multi CNC cutting-edge lathe design and construction quality begins with the machine bed. Profiturn beds use high quality cast iron, with a unique type design for maximum strength and optimum chip clearance. In addition, the lathe bed are mounted on cast-iron base to provide a solid foundation. Sildeways are hardened and specially ground to ensure high-precision, parallel operation of the lathe at all times.

The operator’s console is located for optimum operator convenience and efficiency directly in line-of-sight with the cutting tool. The hand wheels are installed at the ideal ergonomic height for ease of use and have the Profiturn popular “one-click-one-micron” rotational feel sensitivity. The complete operator’s control panel moves on its own independent carriage and rotate 180 degree which allows it to be positioned quickly and effortlessly to the side during loading and setting up.

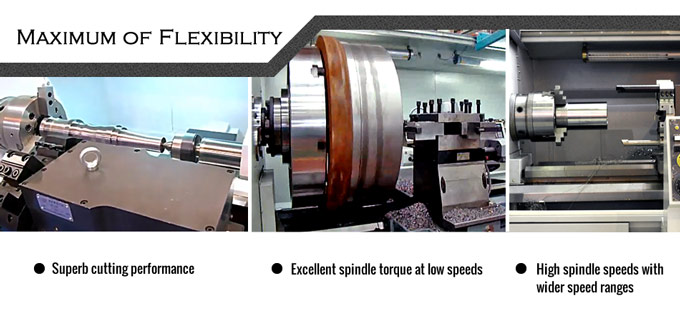

Into the design and development of all Mechatronic Multi CNC lathes goes the technical expertise of specialists Profimach partner companies. Their combined research programs ensure that all new Mechatronic Multi CNC lathes feature the most advanced developments in spindle bearing technology and chuck design. This provides the highest possible spindle speeds and optimum chuck performance for high accuracy turning with maximum load carrying capacity.

Crucial to turning precision and quality is the design and capability of the headstock. These lathes have top rated spindle motors for extra power and more torque in all speed ranges. This means that bottom end torque has been increased by over 75% giving excellent, extremely accurate meta -cutting performance at lower speeds.

The superb new Mechatronic Multi CNC series from Profomach offers a choice of twenty three advanced technology CNC Combination Lathes to suit all types of high-precision turning applications.

All lathes are perfectly suited to producing detailed and intricate one-offs to the highest standard of finish and accuracy. With their advanced CNC control and software systems, they are ideal for turning small-to-large sized batches with fast, high quality repeatability, excellent accuracy and surface finish and most importantly of all, lower component production costs.